|

| March 08, 2022 | Volume 18 Issue 10 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New flame-retardant resin for 3D printing

EPX 86FR is a flame-retardant resin with functional toughness, high strength, and long-term stability.

3D-printing tech company Carbon has introduced an all-new photopolymer resin called EPX 86FR that the company says offers an unmatched combination of flame retardance, functional toughness, high strength, and long-term stability for end-use parts, functional prototypes, and tools that require flame-retardant and self-extinguishing features in the automotive and industrial sectors. Example products are housings, brackets, and connectors. The resin uses Carbon's patented dual-cure process.

Carbon's photopolymer technology uses the digital light synthesis (DLS) technology (originally called Continuous Liquid Interface Production or CLIP) to grow plastic parts from a pool of heated resin -- which was inspired, in part, by a scene in "Terminator 2."

"EPX 86FR was created for critical industries and markets that require a V-0 flame rating, high-performance mechanical properties, and smooth surface quality in a reliable, consistent, and high-throughput printing platform," said Jason Rolland, senior vice president of Materials at Carbon.

EPX 86FR 3D-printing resin is aimed at end-use parts, functional prototypes, and tools that require flame-retardant and self-extinguishing features.

Appliction examples

Astoria Pacific, a company that manufactures automated analysis solutions for laboratories, uses EPX 86FR to develop heat bath housings for highly regulated electronics devices, among other applications.

"We encountered significant supply chain delays in sourcing PVC and sheet metal," said Whitney Menzel, senior engineer at Astoria Pacific. "We turned to Carbon's platform and extensive material lineup, including EPX 86FR, to mitigate these challenges. Not only did we experience a much shorter production time frame using the flame-retardant resin -- from 18 weeks through traditional methods to 2 weeks utilizing Carbon's platform -- but we also saw significant cost savings, enhanced surface finishes, reduced weight, and both thermal and mechanical advantages."

VIDEO: Watch how the parts are made: EPX 86FR deep dive with Carbon's Ikpreet Grover, staff research scientist.

Key features and applications of EPX 86FR include:

- Works well to create end-use parts, functional prototypes, and manufacturing tools for consumer, automotive, and industrial applications that require UL 94 V-0 or FAR 25.853(a) ratings with flame-retardant and self-extinguishing features.

- Similar properties, including functional toughness and temperature stability, to Carbon's high-strength epoxy-based engineering material, EPX 82, with better accuracy from reduced warpage and higher green strength.

- Like other resins in Carbon's unique dual-cure resin portfolio, EPX 86FR produces functional and end-use parts with exceptional surface quality, accuracy, and repeatability.

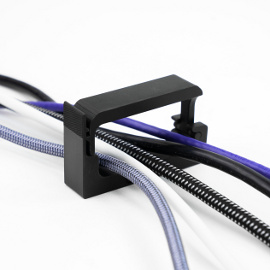

- Target applications of EPX 86FR include: electronics device battery housings, fans, circuit board covers, automotive battery cases, brackets, covers, fasteners, cable clips, and connectors.

EPX 86FR is available to ship in North America, Europe, and the UK and is compatible with Carbon M1, M2, M3, M3 Max, and L1 printers.

Learn more at carbon3d.com/materials/epx-86fr/.

Source: Carbon

Published March 2022

Rate this article

View our terms of use and privacy policy